|

Electrical Power Transformer

Electrical Power Transformer Specification

- Voltage Booster Type

- Dry

- Product Type

- Other

- Material

- Stainless Steel

- Frequency (MHz)

- 50 Hertz (HZ)

- Efficiency

- High

- Phase

- Three Phase

- Usage

- Industrial

- Power Scope

- Electricity

Electrical Power Transformer Trade Information

- Minimum Order Quantity

- 10 Units

- FOB Port

- sonipat

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 25 Units Per Month

- Delivery Time

- 10 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- raping

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Electrical Power Transformer

A power transformer is a crucial static electrical device that plays a fundamental role in the efficient transmission and distribution of electrical energy within a power grid. Its primary function is to change voltage levels from one alternating current (AC) circuit to another without altering the frequency. This allows for long-distance power transmission and safe, usable voltage delivery to consumers.

Why are Power Transformers Essential?

The need for power transformers arises from the physics of electricity transmission:

- Minimizing Transmission Losses: When transmitting electricity over long distances, current causes energy loss (, where I is current and R is resistance). To minimize these losses, the current needs to be low. Since power (, where V is voltage) remains relatively constant in a transformer, stepping up the voltage significantly reduces the current for the same amount of power.

- Safety and Usability: While high voltages are efficient for transmission, they are extremely dangerous and impractical for end-user applications (homes, factories). Power transformers step down these high voltages to safe and usable levels.

Working Principle

The operation of a power transformer is based on Faraday's Law of Electromagnetic Induction and the principle of mutual inductance:

- Primary Winding: An alternating current (AC) is applied to the primary winding, which is a coil of insulated wire wound around a magnetic core.

- Changing Magnetic Field: The alternating current in the primary winding creates a continuously changing magnetic flux within the transformer's core.

- Core's Role: The laminated magnetic core (typically made of soft iron or silicon steel) provides a low-reluctance path for this magnetic flux, concentrating it and guiding it through the windings. Laminations help reduce eddy current losses.

- Secondary Winding: This changing magnetic flux links with the secondary winding, another coil of insulated wire wound around the same core.

- Induced Voltage: According to Faraday's Law, the changing magnetic flux induces an electromotive force (EMF) or voltage in the secondary winding.

- Voltage Transformation: The ratio of the number of turns in the primary winding (Np) to the number of turns in the secondary winding (Ns) determines the voltage transformation ratio:

- Step-up Transformer: If , the secondary voltage (Vs) will be higher than the primary voltage (Vp).

- Step-down Transformer: If , the secondary voltage (Vs) will be lower than the primary voltage (Vp).

- Ideally, the power in the primary circuit equals the power in the secondary circuit, neglecting losses.

Key Components

Power transformers, especially larger ones, consist of several critical components:

- Laminated Core: Made of thin sheets of grain-oriented silicon steel or iron, stacked and insulated from each other to reduce eddy current losses and hysteresis losses. It provides the path for magnetic flux.

- Windings:

- Primary Winding: Connected to the input power source.

- Secondary Winding: Connected to the load where the transformed voltage is delivered.

- These are typically made of insulated copper or aluminum conductors. Larger transformers often have Low Voltage (LV) windings closer to the core and High Voltage (HV) windings placed over them for insulation purposes.

- Insulation: Critical for separating windings from the core, between turns, and between phases (in three-phase transformers). Common insulating materials include transformer oil, paper, and pressboard.

- Transformer Oil (for oil-cooled types): Acts as both a dielectric insulator and a cooling medium. It circulates to dissipate heat generated by losses. (Refer to the "Oil Cooled Transformer" description for more details).

- Transformer Tank: The robust outer enclosure that houses the core, windings, and oil (if oil-filled). It protects the internal components from the environment.

- Cooling System: Methods to dissipate heat. This can range from natural air convection (dry-type) to natural oil convection with air cooling (ONAN), forced air or oil cooling (ONAF, OFAF), or water cooling (OFWF) for very large units.

- Conservator Tank (Expansion Tank): A small tank above the main tank that allows for the expansion and contraction of transformer oil due due to temperature changes, preventing pressure buildup.

- Breather: Contains desiccant (like silica gel) to absorb moisture from the air entering the conservator, protecting the oil from contamination.

- Bushings: Insulated terminals that allow electrical connections to pass through the grounded transformer tank to the windings.

- Tap Changer: A device that allows for adjusting the number of turns in one of the windings, thereby fine-tuning the voltage ratio. It can be an Off-Load Tap Changer (DETC - adjusted when the transformer is de-energized) or an On-Load Tap Changer (OLTC - adjusted while the transformer is energized and supplying load).

- Protective Devices: Such as the Buchholz relay (detects internal faults), pressure relief devices, temperature gauges, and sudden pressure relays.

Types of Power Transformers

Power transformers are categorized based on their application, construction, and cooling methods:

-

Based on Application/Voltage Level:

- Generator Step-up (GSU) Transformers: Located at power plants, they step up the voltage from the generator to very high transmission levels (e.g., 11kV to 400kV).

- Transmission Transformers: Used in substations within the transmission network to interconnect different high voltage levels (e.g., 400kV to 220kV).

- Substation (Step-down) Transformers: Step down transmission voltages to sub-transmission or distribution voltages (e.g., 220kV to 33kV or 11kV).

- Distribution Transformers: Step down distribution voltages to levels usable by consumers (e.g., 11kV to 415V/240V). While often smaller, larger distribution transformers can fall under the "power transformer" umbrella based on their power rating.

- Generator Step-up (GSU) Transformers: Located at power plants, they step up the voltage from the generator to very high transmission levels (e.g., 11kV to 400kV).

-

Based on Phase:

- Single-Phase Transformers: Used for single-phase power systems or can be banked together to form a three-phase unit.

- Three-Phase Transformers: The most common type for power systems, handling three-phase AC power. (Refer to the "Three Phase Power Transformer" description for more details).

- Single-Phase Transformers: Used for single-phase power systems or can be banked together to form a three-phase unit.

-

Based on Cooling Medium:

- Oil-Cooled Transformers: Use mineral oil or other dielectric fluids for insulation and cooling (most common for power transformers).

- Dry-Type Transformers: Use air or solid insulating materials for cooling and insulation, eliminating the need for oil. Typically used for smaller ratings or where fire safety is a major concern (e.g., inside buildings).

- Oil-Cooled Transformers: Use mineral oil or other dielectric fluids for insulation and cooling (most common for power transformers).

Applications

Power transformers are indispensable components at virtually every stage of the electrical power system:

- Power Generation: Stepping up the voltage at power plants for long-distance transmission.

- Transmission Networks: Interconnecting different high-voltage lines.

- Distribution Substations: Stepping down high voltages to lower levels for local distribution networks.

- Industrial and Commercial Facilities: Providing appropriate voltage levels for heavy machinery, motors, and large loads.

- Interconnections: Linking different utility grids.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Power Transformer Category

Oil Cooled Transformer

Price 2000000.0 INR / Unit

Minimum Order Quantity : 10 Units

Voltage Booster Type : Dry

Phase : Three Phase

Usage : Industrial

Efficiency : High

Three Phase Power Transformer

Price 2500000 INR / Unit

Minimum Order Quantity : 10 Units

Voltage Booster Type : Dry

Phase : Three Phase

Usage : Industrial

Efficiency : High

Electrical transformers

Price 250000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage Booster Type : Dry

Phase : Three Phase

Usage : Transformer

1000 kVA Power Transformer

Price 2000000 INR / Unit

Minimum Order Quantity : 10 Units

Voltage Booster Type : Dry

Phase : Three Phase

Usage : Industrial

Efficiency : High

|

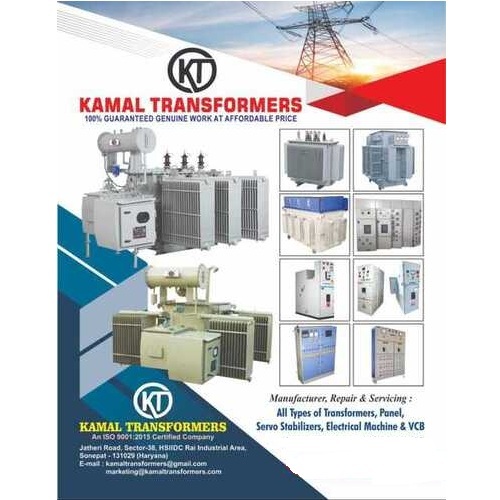

Kamal Transformers

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |